Lard Soap Recipe with Extra Bubbles

Lard Soap recipe with extra bubbles. Soap made with lard is affordable and nourishing to your skin. Lard is an easily accessible fat that makes a wonderful bar of soap! While lard is definitely an old-fashioned soap ingredient, this recipe has a bit of a modern take with coconut and castor oils for extra bubbles!

This post contains affiliate links

What Is Lard?

Some people get lard and tallow confused. The difference is actually very simple. Tallow comes from cattle, deer, or sheep whereas lard comes from pigs. Lard is actually rendered pig fat meaning it has been heated and purified to remove any impurities, it is softer than tallow and is considered a grease. Tallow is rendered leaf fat (fat around the internal organs and kidneys) from cattle. Once cooled from rendering it is a very solid and hard fat.

Learn how to render tallow here. You can follow the same process for rendering lard.

Lard for Soapmaking

Using lard in soap is an age-old practice. Our grandmothers and great-grandmothers made soap with lard for the sake of convenience and availability. We can use this ingredient for the same reasons. Lard can be considered a sustainable by-product.

Lard is cheaper to source than palm oil and likely more widely available. When you use lard you are ensuring that what may be considered waste from the animal is actually used. If you are a homesteader who raises your own meat, you know the sense of honor that you feel for the animal. Most of us desire to use as much of the animal as we can, waste seems irreverent and practically sinful.

Rendering Lard

You can actually follow the same process for rendering lard that you would for rendering tallow. The instructions for rendering tallow are here. You should use the wet method and purify it several times if you plan to use the lard for soapmaking or any other beauty or skin products. This ensures there is no odor.

Benefits of Making Soap with Lard

Lard is moisturizing and nourishing to human skin. It is a mild cleanser that is highly compatible with the structure of our skin cells with a similar pH as well. Oil dissolves oil which means lard soap can actually be good for cleansing your face. It won’t clog pores or damage your skin.

Lard actually has a comedogenic rating of 2 which is lower than coconut oil! Curious about comedogenic ratings for various oils? Check them out here!

Lard is also widely available and affordable, bringing the cost of soap making down considerably!

Essentials for Making Cold Process Soap

- An immersion blender

- A soap mold-you can actually get very creative with this and use things that you have on hand, plastic containers work well. This post shows how to use a cardboard box to make a soap mold!

- Digital Kitchen Scale

- Gloves – I like nitrile gloves, they are stronger than latex and better for use with chemicals

- Goggles

- Instant read Thermometer

- A Rubber Spatula

- Measuring spoons

- Glass bowl or measuring cup for oils

- Extra spoon or spatula for mixing

Lard Soap Recipe

- 30 oz Lard

- 3oz Coconut Oil

- 2 oz Castor Oil

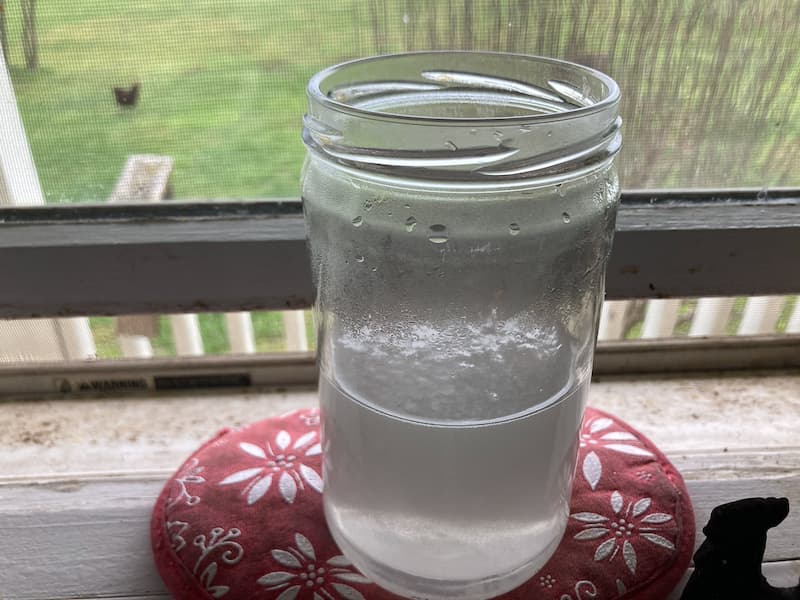

- 10.63 oz purified water or filtered water

- 4.75 oz sodium hydroxide (lye)

Basic Cold Process Soap Instructions

Safety for Soapmaking

Safety: Wear long sleeves, rubber gloves, and goggles or safety glasses

Set up your area and prepare your mold. Clear away anything not related to soap making. Gather everything you will need. Get your immersion blender, your scale, gloves, goggles, and your rubber spatula, bowl, and an extra spoon.

Set out all of the ingredients. You may find it helpful to measure all of the oils and put them in a bowl then put the containers away, just to keep your workspace clear.

I like to put down some cardboard or thick newspaper to protect my counter. I have a butcher block island top and I have burn marks from where I have dripped lye. Plus your spoon from mixing the oils will make a mess too.

Melt Your Fats

In a medium saucepan, melt the fats and oils together. Once melted, set aside to cool.

Mix the Lye

As the fats are melting, measure your water and sodium hydroxide in separate containers using a digital scale. After measured, slowly pour the sodium hydroxide over the water and gently stir. Set this aside to cool in a safe place.

Mix the Lye and Melted Fats

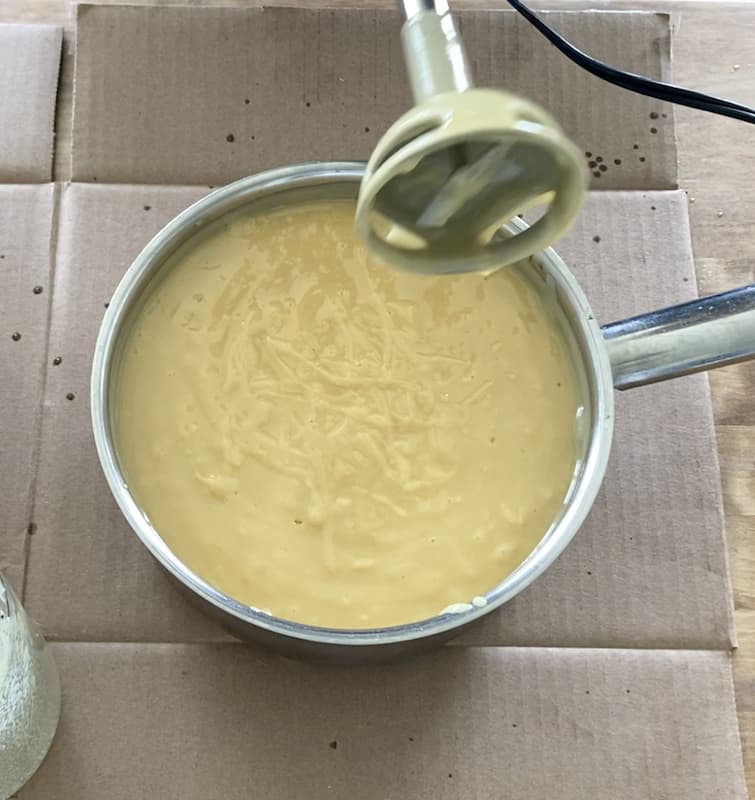

Next, once the lye and the melted fats are cooled to around 115 degrees, or at least within ten degrees of each other and 120 or below, mix the two together. You will do this by slowly pouring the lye into the melted fats, and mix together using an immersion blender.

You should mix with the blender until you reach a thin trace, then add any fragrance oils or colorants that you desire. Mix a bit more and then pour into your mold.

To Gel or Not to Gel?

Next, once the soap is in the mold you can cover it and set it aside for 24 hours. There is a personal preference in soap making regarding whether you should allow or force a soap to go through what is called the gel phase. From my experience gel phase is only necessary for making the color of your soap more vivid. If you are adding color to your soap then forcing your soap to go through the gel phase may be desirable. To do this, you would either wrap your mold in bath towels to insulate and keep the temperature up, or you could put it in the oven at a low setting like 120 degrees.

I think this is a great post on the gel phase.

Personally, I rarely add color to my soap so I do not force or even allow my soap to go through the gel phase. I have had my soap get too hot and crack and I just do not see the benefit. It is absolutely not necessary for making soap. When I make soap with milk, I put the mold directly in the freezer to keep it from overheating and burning. You can do the same with any soap recipe, or you can simply cover it with parchment paper and set it aside on your counter to cool for 25 hours.

Cutting and Curing Your Lard Soap

Lastly, after 24 hours your soap should be hard enough to remove from the mold and cut. Once cut, you simply place the bars of soap on a rack or cookie sheet lined with parchment to cure.

Lard soap is fully cured at 3-4 weeks. Some people say you can use it after 10 days. That again is a personal preference. The longer it cures, the harder the bar will be and the longer it should last as more of the water will have evaporated out of it.

Either way, the bars should be turned from time to time to ensure they dry completely. Airflow around the bars is important.

Lard Soap Video

Printable Lard Soap Recipe

Lard Soap Recipe with Extra Bubbles

Equipment

- 1 Immersion Blender

- 1 Digital Scale

- 1 Digital Thermometer

- 1 Soap Mold

- 1 Sharp Knife or Soap Cutter

- 1 Rubber Spatula or Spoons

- 1 Cardboard

Ingredients

- 30 oz Lard

- 3 oz Coconut Oil

- 2 oz Castor Oil

- 10.63 oz Filtered Water

- 4.75 oz Sodium Hydroxide (lye)

- 2 oz Fragrance or Essential Oil Optional

Instructions

- Melt the lard, coconut oil, and castor oil in a medium saucepan. At the same time, measure the filtered water and the sodium hydroxide.Wearing protective gear, pour the sodium hydroxide over the water. Slowly stir and set aside to cool.Once the fats and oils are melted, set the saucepan aside to cool along with the lye.Once the lye and the fats are cooled to approximately 115 degrees or within ten degrees of each other, you can then mix them together.Slowly pour the lye into the fats. Using the immersion blender, mix the ingredients together. The soap batter will begin to lighten in color and thicken. You are looking for a thin trace. When you reach a thin trace, add the fragrance or color if you are using that. Once you have reached trace, you can pour the batter into a mold.Spray with 99% isopropyl alcohol to prevent soda ash from forming.Let sit in the mold for 24 hours. After 24 hours you can remove the soap from the mold and cut it into bars. Lastly, let the bars cure for 3-4 weeks.

Question- Have you ever added cornstarch to your essential oils to get the scent to stick more? Also, have you tried adding citric acid to the soap for extra cleaning power?

I have not yet tried the cornstarch, my understanding is that it acts as a scent fixative. Arrowroot powder or clay would work the same. I would like to test it on my next soap batch as my fragrances dissipate! The citric acid is used to help combat soap scum I believe. For this, you would definitely want to use a lye calculator as it will neutralize and consume some of the lye. If you don’t account for the lost lye, your soap will be extra superfatted and will then be somewhat slimy. We have soft water so I have not tried this. However, I made liquid dish soap with lemon essential oil and noticed that my glasses are extra sparkly, so I’m wondering if the lemon has a similar effect!

So a long answer to say, no, I have not tried either personally! Ha!

What changes would I need to make to leave out the castor oil

Sorry for the delay. You would need to lower the lye to 4.4 oz for between 6-7% superfat.

Always use a soap calculator to determine changes 🙂 You can find one at soapcalc and on brambleberry websites

Yes!

Thank you for the recipe!

You are welcome!

hi, I know this is an older blog post but the accompanying YouTube video appears to have uploaded incorrectly – only the first few seconds play, and then it’s over. I just tried your beginner soap recipe and loved it! For this lard soap do you have a recommendation on how much EO to use if one were to add some?

Thank you for letting me know! I think I got it all fixed! 2 oz of EO

Excited to make this!

stupid question – are the amounts in weight or volume? and can I use peppermint EO as a scent? thank you!

Weight, and yes whatever fragrance you like!

I tried making lard soap twice.First time went to trace immediately because my lye water was too cold (I had my water frozen) and the whole thing did not mix well,having some spots with lard in it.Second time I replaced the water with concentrated coffee,cold but not frozen.Took forever to get it to trace,and then was too thick all of a sudden.This batch is better,but the heavy lard scent is too strong,even with the coffee and coffee essential oils in it (I probably didn’t use enough essential oil).I have a very sensitive nose,and certain things make me gag or even throw up.I can tell who’s wearing what based on the smell of the clothes,and most ‘naturally unscented’ things don’t go well with me.

I will try making this recipe, but I see that is using a very small amount of lye.Mine was way higher,even though I only used 16 oz of lard,and made it at 8% superfat.May I know why?

like I said,I am a super beginner at soap making,and trying to learn as much as I can.I would like to add some clay too in my next batch.Any chance you would know how much should be added to this recipe?

Thank you.

You must melt your fats and oils before mixing with the lye solution. I suspect you have your temperature too low overall. Try watching the video of me making soap. You can add clay usually about 1 tsp of clay per pound of soap. Mix the clay with a bit of water to make it smooth and then add in before trace. Always double check a recipe with a lye calculator, that is how I came up with the amount of lye to use. Different amounts of fats will require a different amount of lye.

Made it with French green clay and goat milk instead of water, and came out amazing.It is curing now. Can’t wait to use it. Thank you.

I made your lard soap today and poured it into Pringle tubes – Oh, and I doubled the recipe, it filled three Pringle tubes! I processed it at about 10am and cut it about 5pm, as it had hardened. It looked and felt perfect. This will be my go to soap! Love it. I will report back in 4 wks to let you know how it looks and feels. This was such a simple recipe for me (a beginner), thank you so much.

Yay! This made my day! I have never tried to unmold it before 24 hours, even though it was hard enough, there is a risk that saponification is not complete. I’m glad it worked out for you! Thank you for taking the time to let me know how it went! Smart on reusing the pringles containers too! So did you just cut the whole container open? I’m curious!

Hey there! What would happen if I used tallow instead of lard? Would I need to change anything?

You can switch them out, I just double checked with a lye calculator and the lye amount doesn’t change for a 5% superfat. Also, I have a tallow soap recipe, if you don’t want to use milk you can just use water instead.

https://theeverydayfarmhouse.com/cows-milk-and-tallow-soap-recipe-cold-process/